| Shady Climbing | ogv|mp4|webm |

Shady climbing and deploying shade (4x video) | |

Climbing a Structure with Proprioception and Compliance

Shady was developed in the Stata Center at MIT in a room with a large wall-window. We needed some means to block sun glare from hitting our computer screens. Instead of traditional shades which would block the whole window, detracting from the view, we decided to build a robot which can climb on the window’s aluminum frame. It can thus be positioned on the window to be a localized sunshade.

| Shady Climbing | ogv|mp4|webm |

Shady climbing and deploying shade (4x video) | |

Shady is fun, but it’s there’s also some serious robotics research here. While many climbing robots have been developed, only a few climb on thin-member truss-like structures. Shady tests some new ideas in design and control, in particular, using mechanical compliances and associated proprioception, and was experimentally verified to be over 99.8% reliable over many hours of climbing and over one thousand motions.

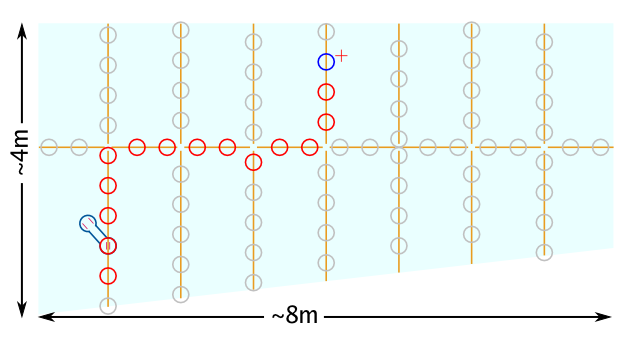

Shady uses a map of the wall-window to plan climbing motions. The frame of the window (yellow lines) is composed of rigid aluminum members, each about 1 inch wide. Shady climbs by a sequence of grip and swing motions, and can climb bars in any orientation. The grippers cannot close at locations where bars intersect, but the need for that can be avoided by starting Shady at an appropriate location.

Shady uses a map of the wall-window to plan climbing motions. The frame of the window (yellow lines) is composed of rigid aluminum members, each about 1 inch wide. Shady climbs by a sequence of grip and swing motions, and can climb bars in any orientation. The grippers cannot close at locations where bars intersect, but the need for that can be avoided by starting Shady at an appropriate location.

Truss-like structures like this include railroad bridges, construction scaffolding, and radio towers. Many structures built in space, for example on the international space station, are also essentially trusses. While most trusses are currently assembled and maintained by humans, it may be advantageous in some cases to have a robot which can climb about the truss to deliver tools and materials, or perhaps to inspect or even assemble new parts of the truss.

While many structure climbing robots have been developed, most do not address the case of climbing on truss-like structures. It can be argued that the penalties for uncertainty are higher when climbing a thin-member truss structure than for some other types of climbing, such as climbing the broad flat surface of a building. In particular, as the robot extends a gripper towards a thin structure it may easily approach misaligned, or even miss the structure completely.

| Shade Deployment | ogv|mp4|webm |

Shady incorporates a deployable sun shade as a demonstration payload. | |

We are most interested in the science and engineering questions related to achieving robust truss climbing. As an example application, Shady carries a deployable sun-shade which can block glare.

Placement of the shade of course depends both on the geometry of incoming sunlight and on the location of the shade target computer screen. We have experimented with automatically calculating the shade location for a particular screen, given the time and date, but in practice we mostly operate Shady by manually specifying its target location.

Other applications for truss climbing robots could include

Shady incorporates two kinds of intentional mechanical compliance. First, the two rotation actuators are mounted on springs which permit about +/-3° of passive rotation. Second, there is a hinge at the center of the robot which also permits about +/-3° of rotation of one gripper with respect to the other, about an axis perpendicular to the gripper rotation axes. The videos below illustrate the operation of both types of compliance.

Importantly, sensors are included to measure the motion at all compliances. These sensors give the robot a proprioceptive sense whereby it can measure the compliant motion at its own joints induced by the robot’s interaction with the environment (both the window frame and gravity). In tests it appears this capability is quite important to ensuring robust operation. As evident in the video below, in many cases when the robot closes a gripper it is initially misaligned with respect to the window frame. The compliances allow the robot to move as needed to conform to the actual local geometry, and the sensing then enables the robot to know how it moved so that it may actively adjust itself to fit that geometry with minimal internal strain.

More details on the implementation and use of compliance and proprioception in this version of Shady are given in our ISER 2006 paper.

| Series Elastic Drive | ogv|mp4|webm |

The gripper rotation motors are mounted on springs which permit about +/-3° of passive sensed rotation. | |

| Active Compliance | ogv|mp4|webm |

Even small external forces are detectable as spring deformations, and the rotation motors are actively engaged to permit the indicated movement. This is convenient for physically configuring the robot. | |

| Compliant Gripping | ogv|mp4|webm |

The gripper rotation springs allow Shady to move slightly each time it closes a gripper, thus conforming the robot to the window frame and accounting for misalignments. In tests this capability seemed crucial to achieving 99.8% reliability over many hours of climbing. | |

| Hinge Compliance | ogv|mp4|webm |

A passive central hinge permits about +/-3° of sensed movement which serves to bias the unconnected gripper towards the window frame. | |

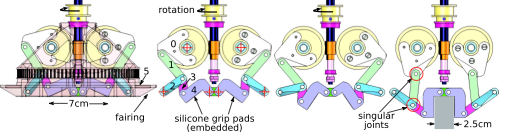

One of the largest engineering challenges for Shady is the design of the grip mechanisms. The window frame geometry does not permit an enveloping grip, and we don’t want to modify it. Thus Shady can only grip the parallel sides of the window frame beams.

We designed a symmetric linkage mechanism to rotate the grip pads to closure. Each half of the mechanism is a pair of coupled four-bar linkages, and each of those approaches a kinematic singularity as the gripper is closed. This gives a high gripping force and virtually eliminates backdriveability. The latter is important both for energy considerations, as no backdriveability means that the grip motors can be left de-energized without fear of the gripper opening, and also for safety, since an unplanned loss of power will not cause the robot to lose its grip.

In testing we found that the choice of grip pad material was critical to avoiding slippage. Currently we use thin sheets of silicone rubber which provide a large amount of stiction against the aluminum window frame without compressing very much.

Finally, we found that closing the gripper on the window frame often results at first in an offset grip (bottom left video). At this point the robot uses its proprioceptive sensors to detect its actual configuration, and then actively adjusts itself to relieve most internal stress. The gripper is then re-opened partially, allowing it to snap down fully onto the window frame, and then closed a second and final time.

More details on the grip mechanism are given in our ISER 2006 paper.

| Gripping (Oblique) | ogv|mp4|webm |

Oblique view of the gripping process. | |

| Gripping (Front) | ogv|mp4|webm |

Front view of the gripping process. | |

| Gripping (End) | ogv|mp4|webm |

End view of the gripping process. | |

| Gripping (Rear) | ogv|mp4|webm |

Rear view of the gripping process. | |

A smaller version of Shady could serve as a module in a self-reconfiguring robot (we have also studied several other designs) when replicated and interlinked with passive free bars instead of gripping a fixed structure. We explored this idea in collaboration with Carrick Detweiler, Yeorem Yun, Seung-Kook Yun, and others in Daniela Rus’ group at MIT. Both a 2D and a 3D version of the idea are possible, the latter enabled by adding a twist actuator between the grippers.

See our ICRA 2006, IEEE RAM 2007, ARK 2010, Springer 2012 publications and Chapter 5 and Appendix K of Prof. Vona’s Dissertation for details.

| Shadydance | ogv|mp4|webm |

Simulation of two Shady modules interacting with a fixed and free bar | |

| Shady Tower | ogv|mp4|webm |

Simulation of Shady modules building a deformable tower | |

Marsette Vona. Operating High-DoF Articulated Robots Using Virtual Links and Joints, Gulrez, Tauseef; Hassanien, Aboul Ella (Eds.). Advances in Robotics and Virtual Reality, Springer Intelligent Systems Reference Library, Vol. 26, Part III, pp. 275-305, 2012.

Marsette Vona. Hierarchical Decomposition and Kinematic Abstraction with Virtual Articulations, Advances in Robot Kinematics, pp. 33-43, June, 2010.

Carrick Detweiler, Marsette Vona, Yeoreum Yoon, Seung-kook Yun, Daniela Rus. Self-assembling Mobile Linkages with Passive and Active Modules, IEEE Robotics & Automation Magazine 14 (4), pp. 45-55, December, 2007.

Marsette Vona, Carrick Detweiler, Daniela Rus. Shady: Robust Truss Climbing With Mechanical Compliances, International Symposium on Experimental Robotics, pp. 431-440, July, 2006.

Carrick Detweiler, Marsette Vona, Keith Kotay, Daniela Rus. Hierarchical Control for Self-assembling Mobile Trusses with Passive and Active Links, IEEE International Conference on Robotics and Automation, pp. 1483-1490, May, 2006.

Marsette Arthur Vona, III. Virtual Articulation and Kinematic Abstraction in Robotics. Ph.D Thesis, Massachusetts Institute of Technology, Department of Electrical Engineering and Computer Science, September, 2009.

Several truss climbing robots have been explored by other groups, e.g. Staritz et al's skyworker, Amano et al's handrail-gripping robot for firefighting, Ripin et al's pole climbing robot, Nechba, Xu, Brown et al's mobile space manipulator SM2, Kotay and Rus' Inchworm, and Almonacid et al's parallel mechanism for climbing on pipe-like structures. Our work with Shady explores a new mechanical design and novel control using intentional mechanical compliances and proprioception, with experimentally confirmed robustness.

In controlled experiments we performed over 10 hours of climbing with this version of the Shady hardware, comprising over 1296 individual grip/ungrip/rotate movements, and including several long uninterrupted climbs. Only two non-dangerous faults were observed in all this testing, yeilding a reliability rate of over 99.8%. This testing is described in more detail in our ISER 2006 paper.